| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Tecon

Model Number : ZT9804S+HD4916B

Certification : CE

Place of Origin : CHINA

MOQ : 1pcs

Price : negotiation

Payment Terms : L/C, T/T

Supply Ability : 16pcs per year

Delivery Time : 5 months after received your payment

Packaging Details : Wooden case

Working hour : 22 hours/day

Air consumption : 1,100L/min

Servo System : Yes

Weight : 30 Ton

Main drive motor : 30kw

Speed : 100-120 pcs/ min

Bearing : (NSK, Japan) No Special Gear

Other : Servo System Control or PLC Control Available

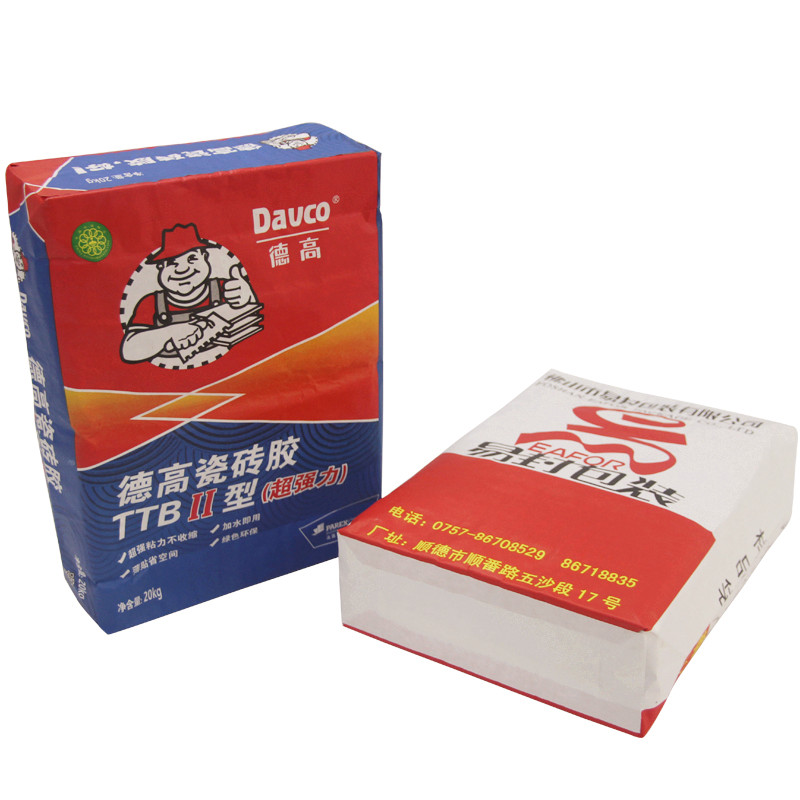

Bag Type : For Cement, Chemicals, Foods, Tea, etc

Printing Color : 4 Colors

Output : 35 - 50 million bags/year

High Speed Cement Paper Bag Making Machine with Servo System

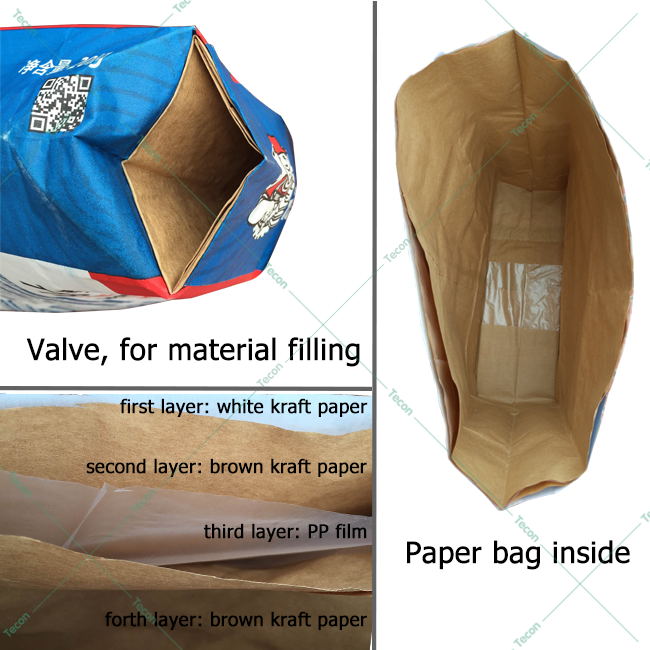

1. Flat & glued bottom with filling valve;

2. Different types for cement, chemicals, foods, tea, etc.

3. 4-color automatic printing

4. 2~4 paper layers, with one extra PE/PP film available

5. 35~50 million bags/year

6. Servo system control or PLC control available, integrated with Photoelectric & Pneumatic control system, Siemens electrical system

7. Full technical service for installation, training and maintenance

8. Full solution for factory construction and materials purchase.

Bottomer Machine’s Process Description

Step1 High-speed Rotary Vacuum Feeding

Step2 Puncturing Vent Hole and Creasing

Step3 Tubes Delivery

Step4 Bottom-Opening

Step5 Valve Sheet Pasting

Step6 Automatic Gluing

Step7 Bottom-pasting and Bag Forming

Step8 Bottom Revising

Step9 Bags Counting and Palletizing

Step10 Programmable Logic Controller(PLC)

ZT9804S Tuber Machine

Performance

| | 80~120 tubes/min(Depends on paper quality, number of ply and operators’ skill.) |

| Tube length | 400~1400 mm |

| Tube width | 380~620 mm |

| Type of cutting | Step cut&Flat cut |

| Number of ply | 2~4 paper + 1 PP/PE(Please specify if you need paper bag with PP film) |

| Printing width | 1300 mm(MAX) |

| Paper reel width | 660~1260 mm |

| Paper reel diameter | Max. 1, 300 mm |

| Main drive motor | 47kw |

| Size of whole set | 35.3m×2.4m×2.7m( L×W×H) |

| Total weight | 32 T |

Composing of the machine

ZT9804S Tuber Machine

| Name | Quantity |

| 4-color printing machine | 1 |

| Paper reel stands | 5 |

| Paper web guide | 1 |

| Automatic paper rectifier | 1 |

| Auxiliary paper driver | 1 |

| Perforation unit | 1 |

| Latitudinal gluing machine | 1 |

| Longitude gluing machine | 1 |

| Tubes forming unit | 1 |

| Driving tearing-off unit | 1 |

| Delivery and counting unit | 1 |

| Electric control system | 1 (Schneider) |

| Air compressor | 1 |

| Servo system | 1 |

HD4916B Bottomer Machine

(bottomer with strength sheet pasting unit)

Operating condition

| Working hour | 22 hours/day |

| Design temperature | 0~40℃ |

| Design humidity | MAX. 95% |

| Number required | 1 unit |

| Model name | HD4916B |

Performance

| Max Speed | 110 bags/min(Depends on paper quality, number of ply and operators’ skill.) |

| Bag length | 520~880mm |

| Bag width | 420~600 mm |

| Bottom width | 90~160mm |

| Bottom open width | 200~440mm |

| Distance between bottom centers | 420~780mm |

| Valve sheet length | 100~300mm(adjustable) |

| Valve sheet width | 120~240mm(adjustable) |

| Main drive motor | 33kw |

| Total weight | 25T |

| Size of whole set | 23.5m×1.8m×1.8m ( L×W×H) |

| Valve sheet reel diameter | Max.1,300mm |

| Number Patch Length | (2~4)layers+1PP film |

Composing of the production line

HD4916B Bottomer Machine

(bottomer with strength sheet pasting unit)

| Name | Quantity |

| High speed feeder machine | 1 |

| Perforation of the exhaust outlet unit | 1 |

| Tube opening unit | 1 |

| Automatic gluing machine | 1 |

| Scrip sealing machine | 1 |

| Bag bottom turning unit | 1 |

| Counting and delivery line | 1 |

| Automatic delivering out unit | 1 |

| Piling up platform | 1 |

| Electric control unit | 1 (German Siemens) |

| Vacuum-pump | 1 (German Rietschele) |

| Bearing | (Janpan NSK) |

Foshan Tecon Package Machinery CO., LTD is a high-tech equipment manufacturer.

We designed the first production line for paper bag 20 years ago, that's is about 1996, and now we are listed in the world top three in this industry and the only one in China able to design & manufacture the whole production line of bottom sealed paper bag.

The leading product of our company is the "high-speed automatic bottom-pasted bag making machine". It is composed of a tuber machine and a bottomer machine.

|

|

High Speed Cement Paper Bag Making Machine with Servo System Images |